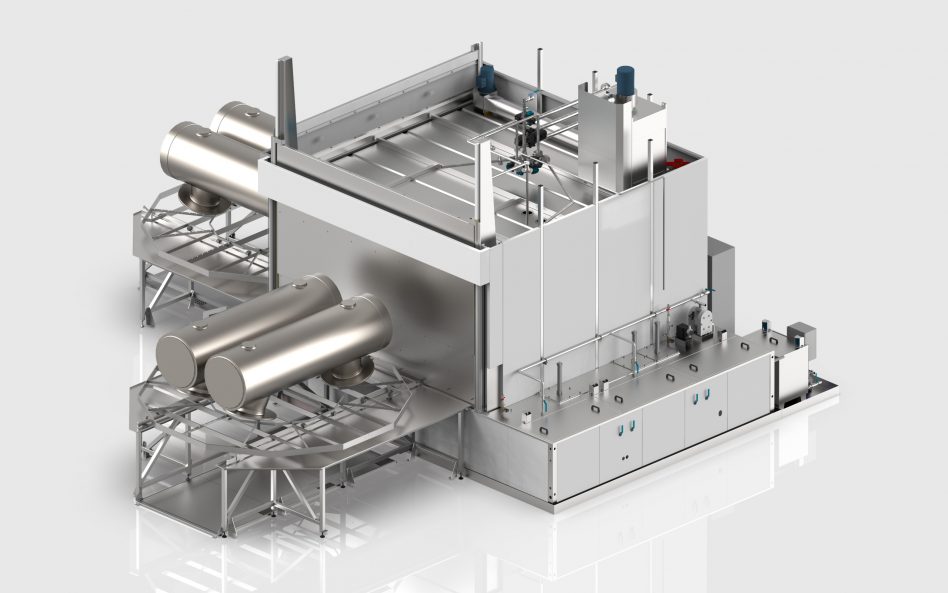

Robust build on stainless steel 304L

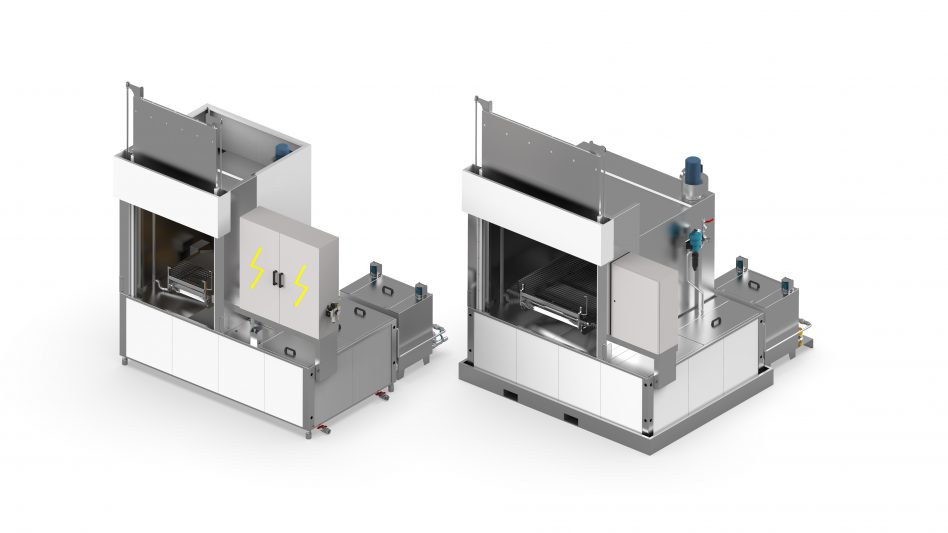

The MB mechanical parts degreasing machine is divided into a range of 6 standard models depending on dimensions, weight and quantity of parts to be cleaned.

MB 8 > Length 32″ x Width 32″ x Height 32″ (800 x 800 x 800 mm)

MB 10 > Length 40″ x Width 40″ x Height 32″ (1000 x 1000 x 800 mm)

MB 13 > Length 52″ x Width 52″ x Height 32″ (1300 x 1300 x 800 mm)

MB 15 > Length 60″ x Width 60″ x Height 32″ (1500 x 1500 x 800 mm)

MB 18 > Length 71″ x Width 71″ x Height 32″ (1800 x 1800 x 800 mm)

MB 20 > Length 79″ x Width 79″ x Height 32″ (2000 x 2000 x 800 mm)

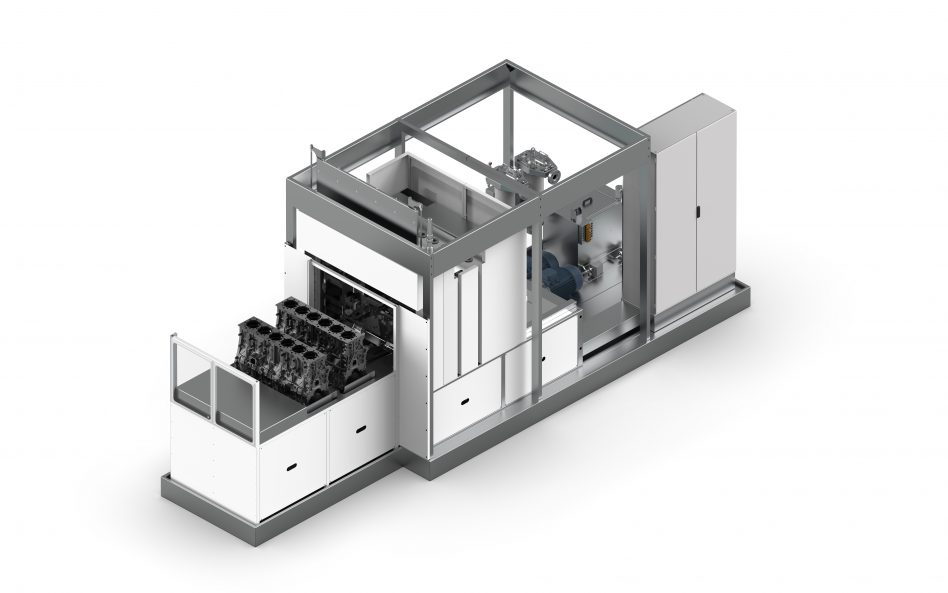

The MB machine puts its robustness to the test in many heavy goods vehicles such as heavy trucks and railway maintenance workshops.

Standard payload up to 4,400 lbs (2 tons)

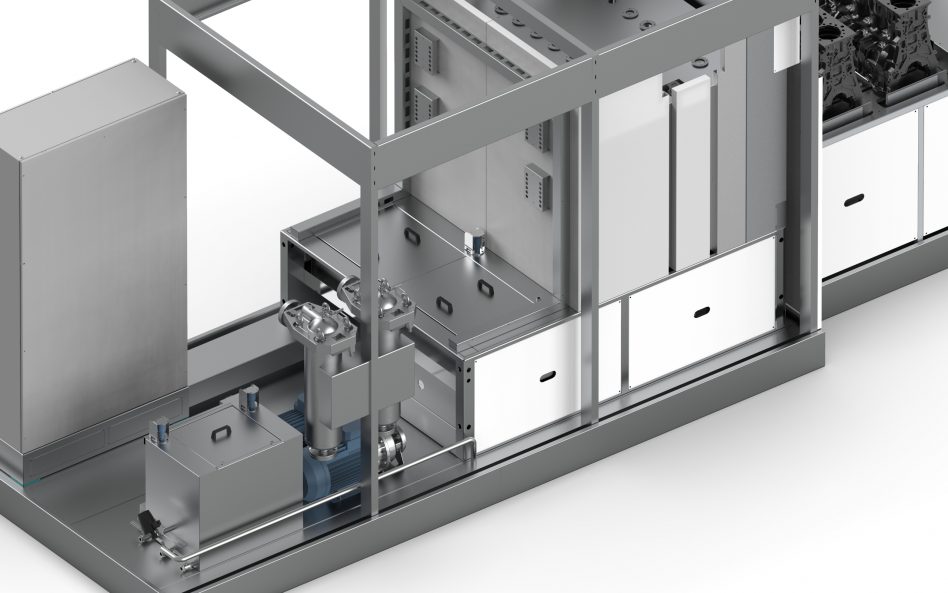

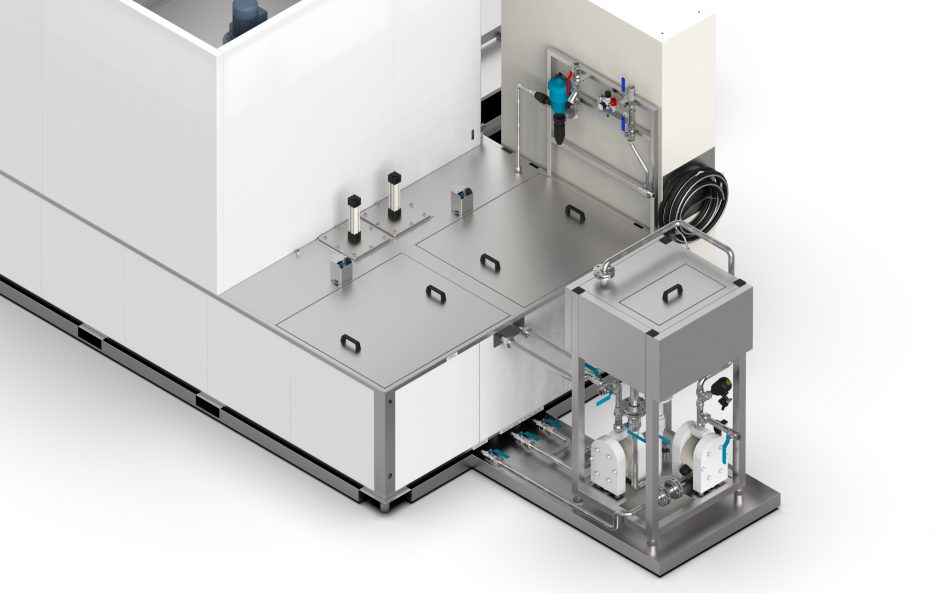

Overflow coalescence oil skimmer

Rolling paper filter

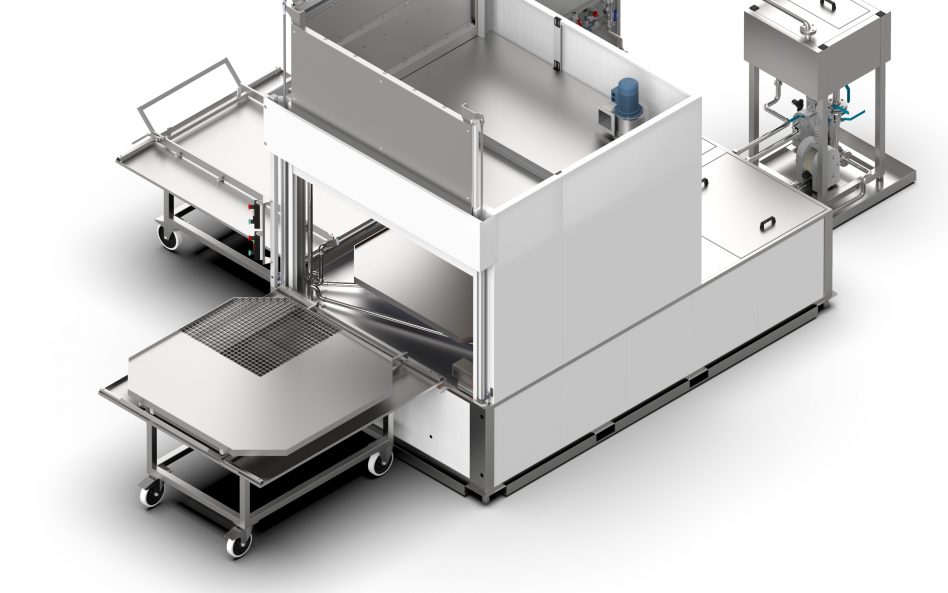

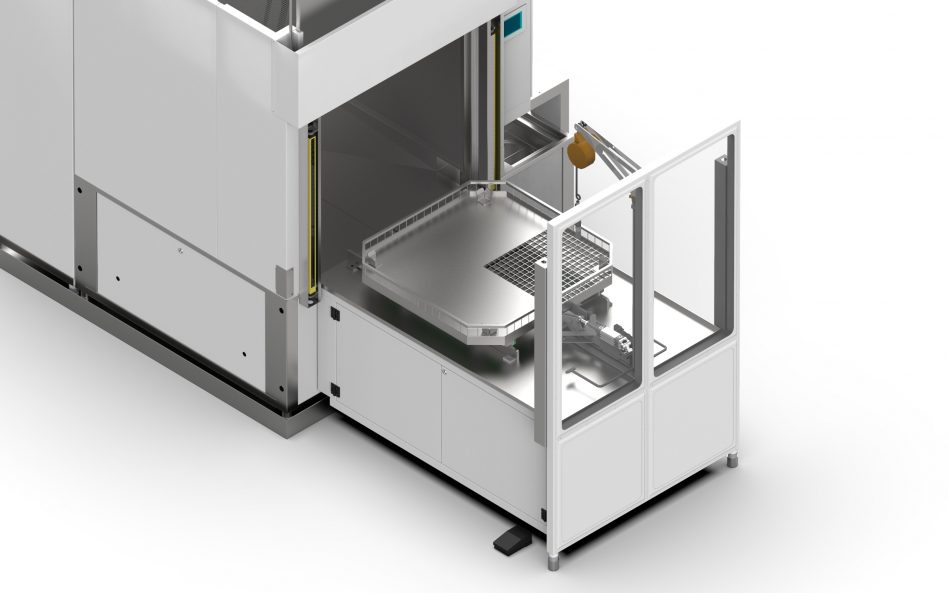

Depending on the parts dimensions to be cleaned, the cleaning chamber is adapted and equipped accordingly.

Custom made working chamber

Pit machine

Automatic dosing and filling

Fine filtration

Custom fixtures

Solve our customer cleanliness issues by finding out the best Industrial parts washers. Our industrial parts cleaning machines can be perfectly adapted to your production lines.

Depending on your parts, contaminants and cleanliness requirements, together we can define the most appropriate process for cleaning your industrial parts, using our machines and different technologies.

Discover our cleaning technologies adapted to each of the sectors in which we operate. From the automotive sector to aeronautics and railways. We offer parts cleaning solutions for the medical, oil and general industrial sectors.