Under 27 ft² floor space

6 to 8 loads per hour

Drum oscillation or rotation

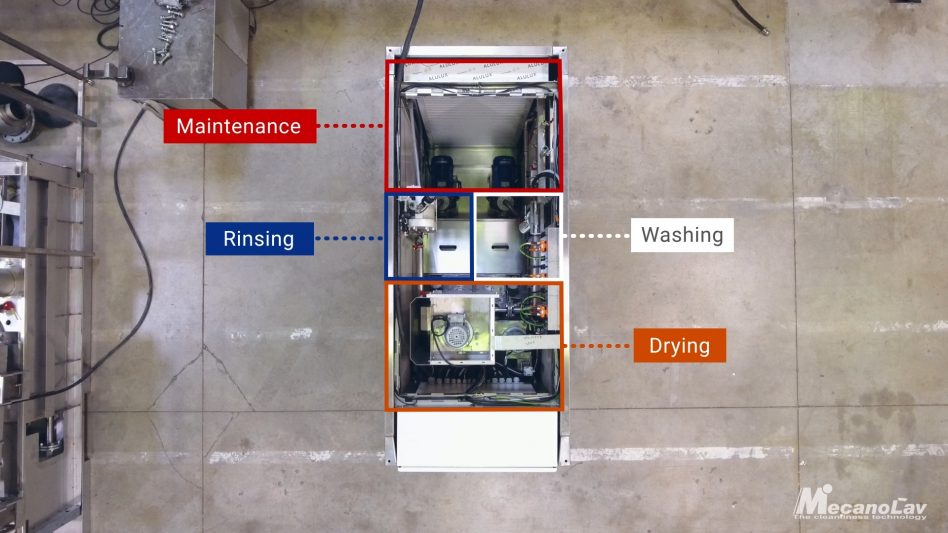

Modular cycle : washing, rinsing, drying

Closed circuit operation

Option of overhead or vertical door

The one piece design MecanoJET is basically adapted for production shop who need floor space, especially in the bar turning business.

Width 37 3/8” ( 950 mm )

Easy to integrate in production line

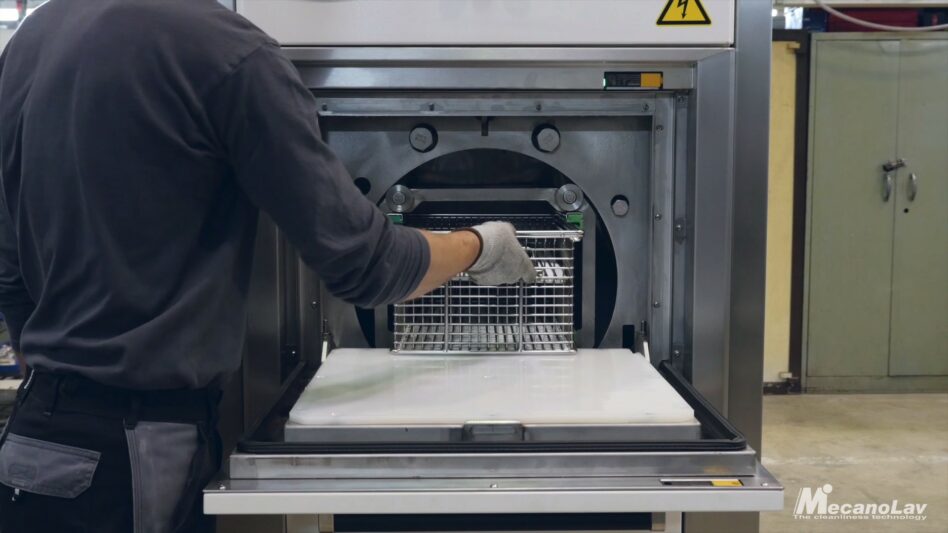

The MecanoJET Compact machine is dedicated for small parts allowing a processing capacity from four to six loads per hour, achieving high levels of cleanliness and great flexibility.

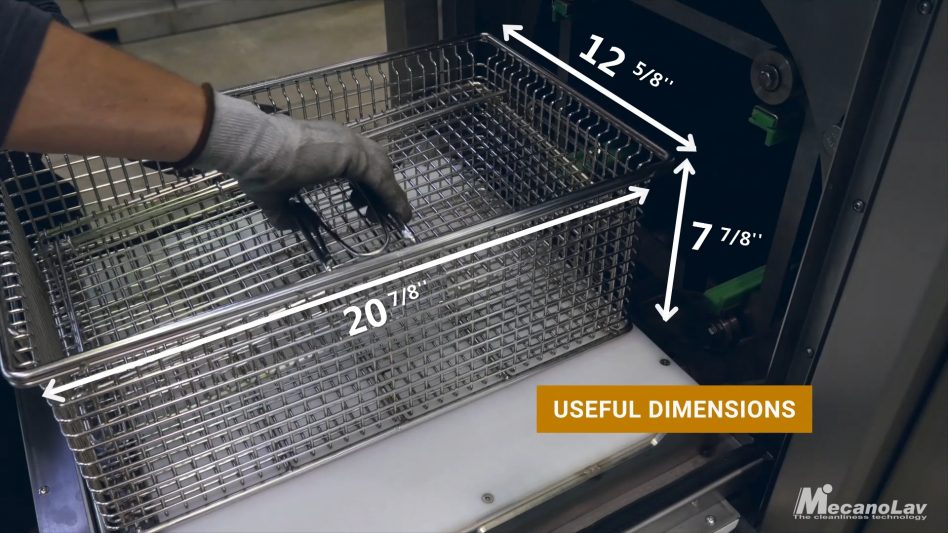

The MecanoJET Compact can process baskets or palets with dimensions up to 20 7/8″ x 12 5/8″ x 7 7/8″ (530 x 320 x 200 mm).

Her older sister, the MecanoJET can process large loads up to manufacturing of a custom-made drum.

For each part number, the MecanoJET Compact has the possibility to select between full rotation or drum oscillation.

Full rotation > closed basket / non-sensitive parts or clamped in position

Oscillation with a set angle > workpiece carriers / sensible parts

To achieve great degreasing performances, the MecanoJET Compact is equipped with two separated tanks.

The cleaning recipes can be adjusted depending on cleanliness requirement and the parts to be cleaned.

Spray washing step

Spray rinsing step

Hot air blowing and/or drying step

The MecanoJET Compact is equipped with a touch screen interface allowing a user friendly utilization for technician.

Part program recipe

Process parameters visualization

Parameters modification

Machine alerts and faults management

Traceability with washing report editing

Design to be easily maintened, the MecanoJET Compact ensures a wide maintenance access at the rear by a shutter roller.

Filters easy access

Drain pump with integrated rod

Spray gun included for maintenance

Mixed detergent in automatic

Automatic cascade refilling

Oil skimmer

In standard, the machine is equipped with masters and I/O links modules allowing troubleshooting on machine issues.

Immediate detection wire breakage or signal

No losses of measured values

Plug & play sensors replacement : reconfiguration not need it

In standard version, the MecanoJET Compact come with a manual opening/closing tilt door, as an option it can be equipped with a vertical door which will open automatically at the end of the cycle.

Overhead door ensuring the loading station action

Vertical door with steady working station

MecanoLav’s DNA consists in adapting our machines to the cleaning problems for our customers. Being a standardize solution, the MecanoJET Compact is no exception to this rule.

Armored stainless build : valve bodies stripping

Solve our customer cleanliness issues by finding out the best Industrial parts washers. Our industrial parts cleaning machines can be perfectly adapted to your production lines.

Depending on your parts, contaminants and cleanliness requirements, together we can define the most appropriate process for cleaning your industrial parts, using our machines and different technologies.

Discover our cleaning technologies adapted to each of the sectors in which we operate. From the automotive sector to aeronautics and railways. We offer parts cleaning solutions for the medical, oil and general industrial sectors.