Assurer la qualité du dégraissage avant le processus de traitement thermique

Des solutions de nettoyage adaptées pour la maintenance et la révision

Maîtriser tous les types de médias de nettoyage : solvant chloré, détergent, solvant hydrocarbure

Garantir une propreté spécifique en termes de gravimétrie et de granulométrie

Apporter une réponse spécifique pour le lavage des tubes

Nos équipements assurent un process de nettoyage de vos pièces mécaniques en fonction de votre application et fonctionnement amont/aval :

Avant le traitement thermique

Avant traitement de surface

Avant contrôle dimensionnel

Avant revêtement / peinture

Nettoyage inter-opérations

Lavage final

L’objectif du dégraissage avant traitement thermique est d’éliminer toutes les contaminations qui peuvent provoquer un traitement inégal, et également d’éviter la contamination des fours.

Various different issues are found : stored parts, bulk parts, different geometries and diverse materials with a long list of different contaminations. Surface Alliance Cleaning Corporation support you to find the appropriate cleaning solution.

Tough and dry contamination are representative of mechanical parts in the rebuild and maintenance field.

Surface Alliance Cleaning Corporation has over 100 years of cumulated how-know with heavy tractor trailer, light vehicle overhaul, handling machine and nautical equipment. The product line ECO, MAXIMA and MB are design to accept large and heavy parts up to several tons.

To prevent mechanical blockage and rapid wear on precision components such as the roller screws, a proper final wash is necessary to meet all the cleanliness requirements in tern of gravimetry (<2mg) and particle size (200µm)

The MecanoFAST system with his short cycle time, the POWERJET using ultrasound or the SOLVACS operating with vacuum solvents; Each of these system have the capacity to ensure the decontamination of the parts according to their complexity.

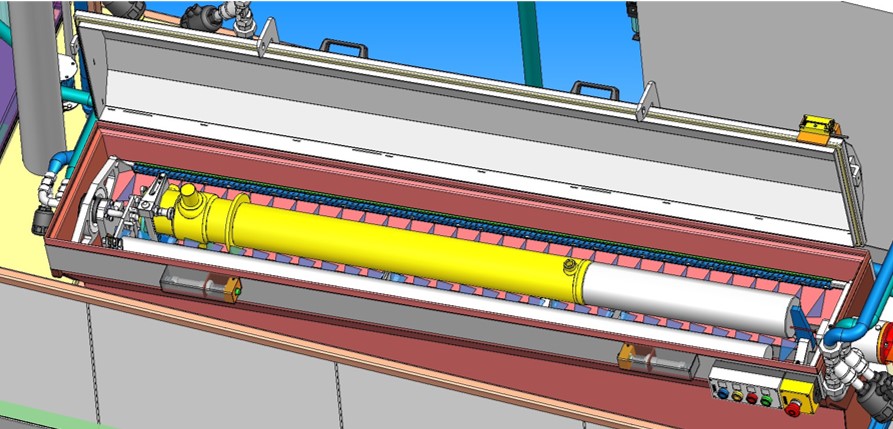

The cleaning of the tube ID, wether they are bent or straight required intense mechanical action by flushing or via a mechanized serynge tool to effectively remove particles and contamination from the surface.

Solve our customer cleanliness issues by finding out the best Industrial parts washers. Our industrial parts cleaning machines can be perfectly adapted to your production lines.

Depending on your parts, contaminants and cleanliness requirements, together we can define the most appropriate process for cleaning your industrial parts, using our machines and different technologies.

Discover our cleaning technologies adapted to each of the sectors in which we operate. From the automotive sector to aeronautics and railways. We offer parts cleaning solutions for the medical, oil and general industrial sectors.