3 working chamber sizes as standard

Flexible and modular process depending on the application

Cleaning by simple or special immersion method with ultrasound

Compatible with Cyclic Nucleation process (CNp)

Parts packaged by bulk batches, stored or on pallet

Designed for high quality cleanliness requirements

High processing capability with low operating cost

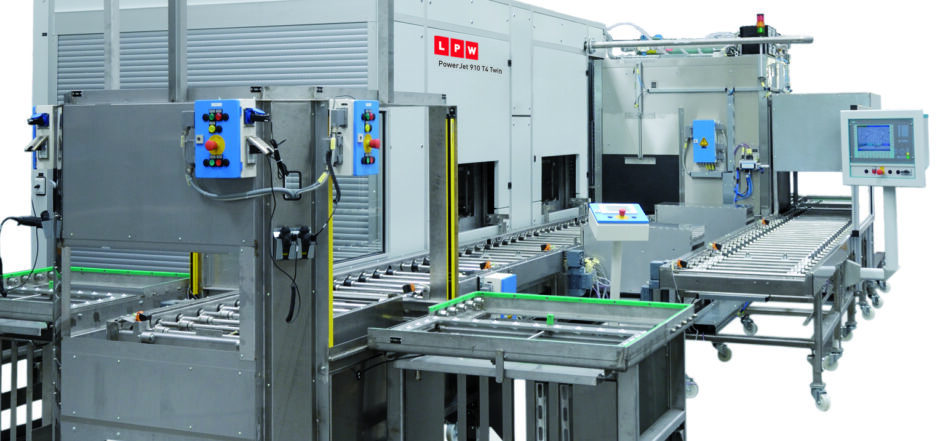

Manufacturing by our partner LPW Reinigungssysteme GmbH

The PowerJet cleaning machine is available in 3 standard overall dimensions depending on the size of the parts to be processed and the volume of parts to be processed.

For special applications, the working chamber can be custom-made.

PowerJet 530 > 530 x 320 x 200 mm

PowerJet 670 > 670 x 480 x 300 mm

PowerJet 960 > 1020 x 650 x 560 mm

The PowerJet allows the use of the well-known cleaning and drying processes according to the expected cleanliness requirements.

Its flexibility allows the treatment of highly contaminated parts as well as the disinfection of medical devices (MD).

Spraying – Simple or special flood cleaning – Ultrasound – Cyclic nucleation (CNp)

Hot air drying – Vacuum drying

When applications require a separation of each cleaning steps or when the production rate requires saving processing and loading time, the PowerJet is a standard machine in a multi-chamber version.

PowerJet Twin > 2 chambers

PowerJet Triple > 3 chambers

Operating in a closed circuit, excellent fluid treatment is essential to achieve repeatable cleanliness results and drains the bath regularly.

Oil skimmer

Distillation for aqueous solution treatment

By-pass filtration for continuous bath treatment

The loading and unloading of the PowerJet system is fully automated with an automatic conveyor integrated with the machine.

In the case of multi-chamber machine especially in final washing in a high pace environment, it allows the loading and unloading of parallel chambers simultaneously.

Flood cleaning consists of constant pressure changes in combination with the basket rotation.

The working chamber evolves from overpressure to depression, producing reverse flow variations to clean cavities and deep drilling.

PowerJet flood washing is particularly effective on surface contamination and chips.

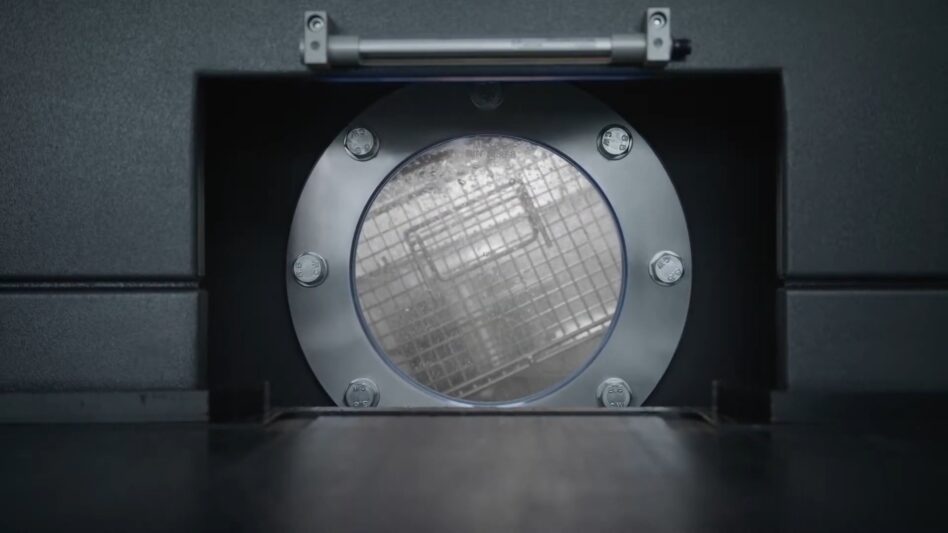

Ultrasound diffuses into the fluid and generates cavitation and micro-currents that allow to clean parts. The lower is the frequency, the more intense is the action.

Depending on the fragility of the material and the adhesion of the contamination, the frequencies to be used are different:

25 to 40 kHz > general industry and automotive

40 to 120 kHz > jewellery, optics, medical, electronics

250 kHz to 1 MHz > semiconductors, precision components, nanotechnology, photovoltaics etc…

CNp technology ensures an ultra-efficient cleaning of complex geometries such as grooves, blind holes and narrow channels without attacking the surface of the parts. As part of the PowerJet, the CNp opens up new cleaning opportunities in many areas:

Cleaning capillary components

Depowdering after additive manufacturing

Disinfection of medical instruments (MD)

For highly sensitive cleaning applications, PowerJet’s design is upgraded to be a transition between the grey room and the cleanroom.

Member of the Surface Alliance, LPW is leader of the group for high cleanliness requirements with aqueous solution, using ultrasound and CNp process.

Washtec represent the LPW Reinigungssyeteme GmbH cleaning machines for the North American business.

Solve our customer cleanliness issues by finding out the best Industrial parts washers. Our industrial parts cleaning machines can be perfectly adapted to your production lines.

Depending on your parts, contaminants and cleanliness requirements, together we can define the most appropriate process for cleaning your industrial parts, using our machines and different technologies.

Discover our cleaning technologies adapted to each of the sectors in which we operate. From the automotive sector to aeronautics and railways. We offer parts cleaning solutions for the medical, oil and general industrial sectors.