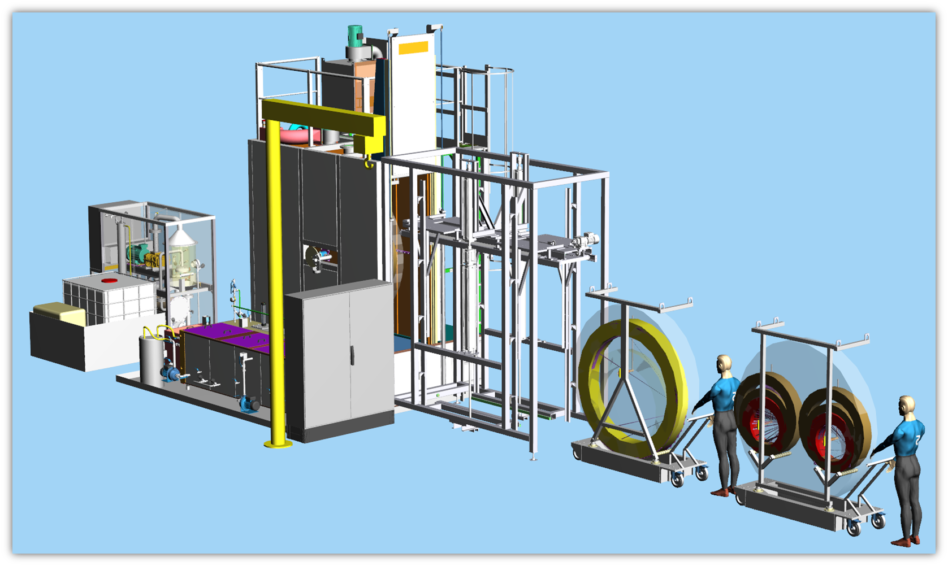

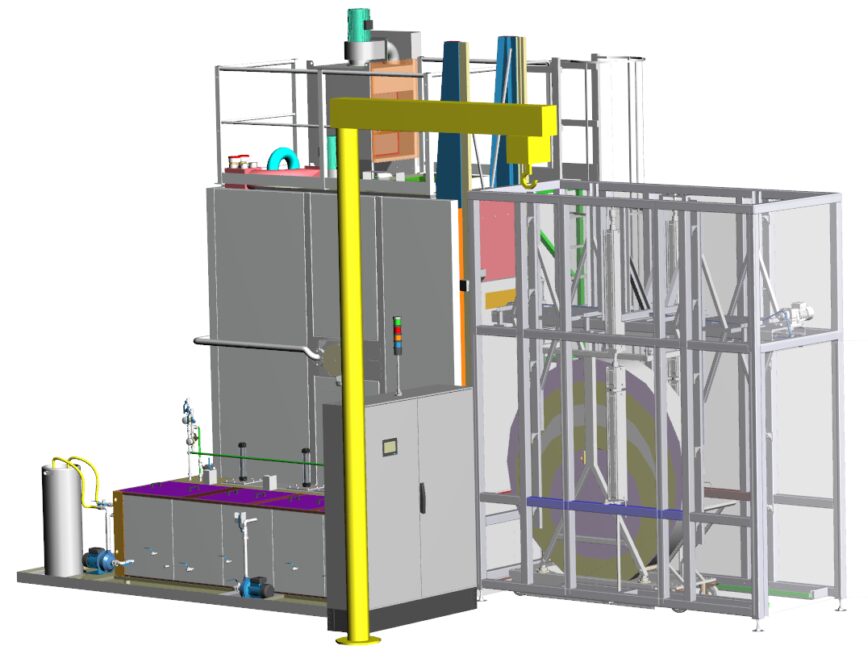

Following the solicitation of an aircraft engine manufacturer, we designed and manufactured a cleaning machine with an automatic custom made loader to clean straighteners.

Dimensions of straighteners to be degreased :

Contamination > oil, chips, penetrant product.

The machine is designed to meet Class A, B and C specifications and be in NADCAP compliance.

Cycle time per load, 27 minutes including loading and unloading.

The part is loaded manually upstream on a safe zone with an attached carrier, then the loading system will charge it automatically in the degreasing machine.

Rotational spraying tools are located as close as possible to the parts to ensure a proper degreasing. The part recipe is automatically adjusted to achieve the expected cleanliness requirement and to meet the surface tension required.

In addition to serial filtration, resins, measuring instruments for the rinsing conductivity, a CMV evaporator ensure a process repeatability and an optimal quality of each tanks.