Several OEMs in the automotive industry have already asked us to develop machines to clean injection ramps (Common rail), after machining, before assembly and leak test, in robotic cells.

2 different parts reference are washed simultaneous in less than 37 seconds.

Contamination -> cutting oil and chips

ID / OD cleaning according to the following criteria :

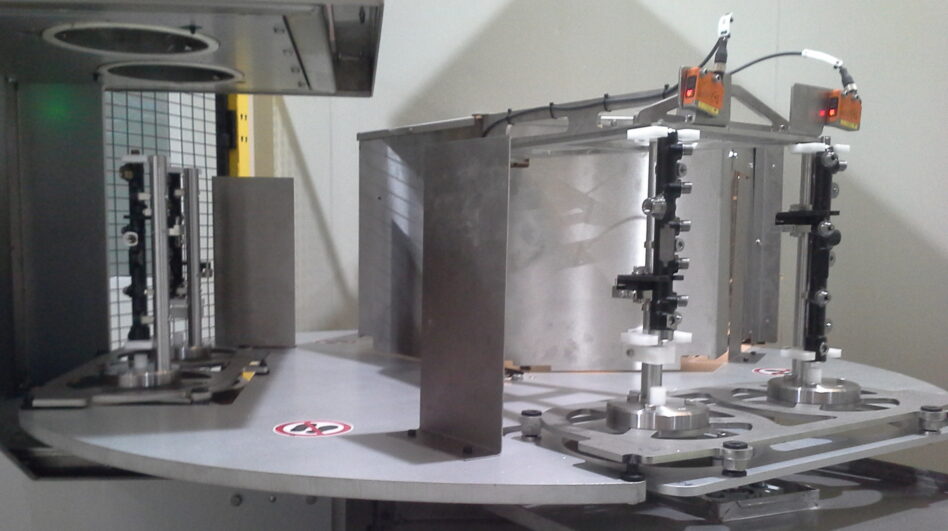

The parts are loaded vertically by a robot and automatically clamped on a custom-made pallet.

The 3-positions rotating table allows you to load parts in masked time and to unload by a second robot in the clean room. In case of the robot is not working properly, loading is still possible in manual mode secured by light curtains.

A specific washing and drying tool performs the cleaning of the part (OD). An optimized syringe with oscillating movement cleans and dries the inside of the injection ramp (ID/ports).